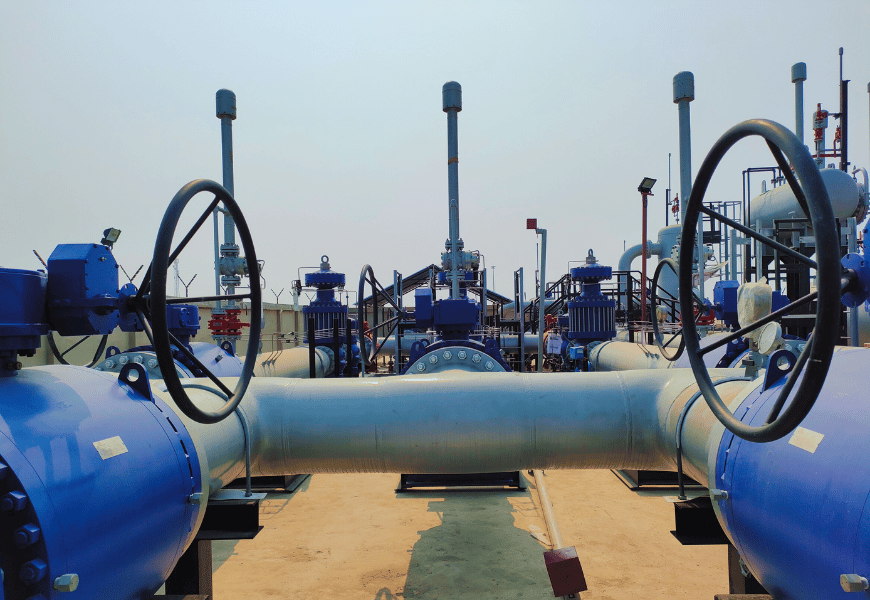

At PDSB, we deliver top-tier instrumentation solutions. We ensure precision and reliability in industrial processes. This guide gives a brief overview of our installations. It covers pressure and temperature measurements, valve operations, and tubing.

Pressure transmitters measure the pressure of gasses or liquids and convert this measurement into an electrical signal readable by control systems.

Installation Steps:

Temperature transmitters measure the temperature of a process and convert it to an electrical signal.

Installation Steps:

These gauges measure the pressure difference between two points in a system, crucial for applications such as filter monitoring and flow measurement.

Installation Steps:

Differential pressure transmitters give an electrical signal based on the pressure difference between two points.

Installation Steps:

Temperature control valves regulate the temperature of a process by controlling the flow of a heating or cooling medium.

Installation Steps:

These electrically controlled valves start or stop fluid flow in a system quickly and reliably.

Installation Steps:

Pressure regulators maintain a constant output pressure despite variations in input pressure.

Installation Steps:

These safety devices immediately stop the flow of gas or liquid in emergencies.

Installation Steps:

Burners are used in heating applications such as boilers, furnaces, and ovens.

Installation Steps:

At PDSB, we ensure your industrial processes run smoothly and safely. Each instrument requires precise installation for accuracy and reliability. Regular calibration, testing, and maintenance are essential. Trust PDSB for your instrumentation needs, where precision meets reliability.

We adhere to strict industry standards and regulations, using high-quality materials and experienced professionals.

Yes, Prince Dockyard & Ship Builders has extensive experience in managing both small & large-scale industrial projects efficiently and effectively.

Yes, we tailor our services to meet the unique requirements of each client, ensuring optimal results and satisfaction.

Our team consists of highly qualified and experienced professionals in the fields of engineering, construction, and project management.